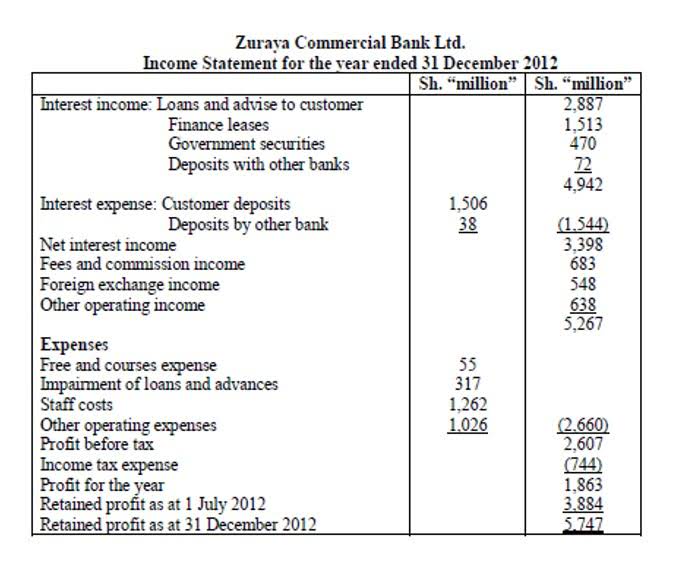

Your company calculates the cost of direct labor or the cost according to the output of each stage? Viindoo software allows you to set the corresponding labor cost calculation. When the production order is completed, the system automatically calculates labor costs according to the actual number of hours or the actual output that you have entered the system. The manufacturing cost is virtual accountant very important for businesses to determine the selling price of a product. By understanding the production costs, businesses can identify areas of waste to reduce costs and increase profits. Accounting for manufacturing overhead costs is comparatively easy, as these tend to be fixed costs, and manufacturing overheads typically stay the same when ramping up production.

- If your findings in this area aren’t favourable, you can at least use the data as fuel to remedy the situation.

- There are always some materials that get used up but don’t go into the finished product.

- If you’re a manufacturing company, knowing how much it costs to produce your goods will help you determine how much profit margin you need to stay competitive with other companies in the same field.

- Also, technological advancements have led to the manufacturing sector becoming increasingly automated, which has increased the production of goods.

- It’s important to distinguish between direct and indirect manufacturing costs.

- He’s not making as much profit as he’d hope and he thinks it’s because his coffee isn’t priced correctly.

- We understand what direct material costs are so now it’s time to talk about the formula used to calculate them.

The Best Manufacturing Quoting and Estimating Software

It also includes related payroll taxes and expenses such as social security, Medicare, unemployment tax, and worker’s employment insurance. Companies should also include pension plan contributions, as well as health insurance-related expenses. Some companies may include employee training and development costs that total manufacturing cost formula were incurred in the course of employment. The cost of labor includes employee pay, benefits, labor taxes and contributions, and workers’ compensation insurance.

Formulas to Calculate Manufacturing Costs

Book a call with a Thinaer manufacturing expert today to explore how our solutions can be customized to meet your specific needs and take your manufacturing process to the next level. In these cases, ABC isn’t going to work because it requires computers to operate effectively. If there is a high demand for a particular raw material, then this will increase its price. Because if more people want it, there is less available, so the price goes up.

Subscribe to the aPriori Blog!

The tax rate has increased in many areas of the country, meaning that companies will cost more to manufacture their products. So for every pair of headphones you make, it will cost $120 in direct labor costs. Knowing the cost of manufacturing a product is more than being able to calculate the price and profits of the item.

- It’s much easier to work out total manufacturing cost when the latest financial data can be accessed at the click of a button, and when the information from all departments is inter-connected.

- However, such costs are required in the production process of goods and must, therefore, be added to the overall cost of the product.

- By having less produce in the warehouse at any given time, fewer storage costs are incurred, and your facility is far more organised as a result.

- Such costs can be determined by identifying the expenditure on cost objects.

- These are the hours spent by workers who are directly contributing to the production process.

- Thinaer® revolutionizes manufacturing by filling in digital blind spots through IIoT asset tracking and digital twins to enable smarter production decisions in commercial and classified environments.

Fundamentally, the benefit of accurately calculated total manufacturing costs lies in reducing financial risk. Even if a business is profitable on paper, cash flow difficulties can sink the enterprise. Staff not handling the production of goods, such as management, accounting, maintenance, cleaning staff, etc. are not considered direct labor.

These workers are responsible for converting the raw materials into the finished goods. Calculate manufacturing overhead costs by summing up your facility’s indirect expenses. View examples and formulas and learn how to calculate predetermined overhead rate.

The term fixed manufacturing overhead refers to all factory overhead costs that do not depend on the production volume of a manufacturing business. A manufacturing overhead budget covers all fixed, variable and applied manufacturing overhead costs of an organization. These costs are then allocated to each unit that’s produced and documented as part of the cost of goods sold in a manufacturer’s master budget. As the name implies, these are financial overhead costs that are unavoidable or can be canceled. Among these costs, you’ll find things such as property taxes that the government might be charging on your manufacturing facility.

Considering its significance, let’s dive into this article to understand what exactly it means, its components, how to calculate it and many benefits that come from knowing it. Determining manufacturing overhead expenses also helps with budgets for manufacturing overhead. Knowing your manufacturing overhead costs means you can budget the money needed to cover these costs. Producing too much stock in advance means you are spending a lot more on direct material costs. Equally, you will also incur the costs adjusting entries of holding excess inventory stock or risk being left with stock you cannot sell. The key difference between direct costs and indirect costs is that direct costs can be tracked to specific item, and tend to be variable.

How to calculate manufacturing overhead

Manufacturing overhead is considered an indirect cost, as it’s not directly related to the product. However, it falls into its own category as a type of indirect cost because manufacturing the product cannot take place without these overhead expenses. Robust MRP systems can track production costs both per period, per project, or per product, making them suitable for both job shops as well as make-to-stock manufacturers.